Edit Content

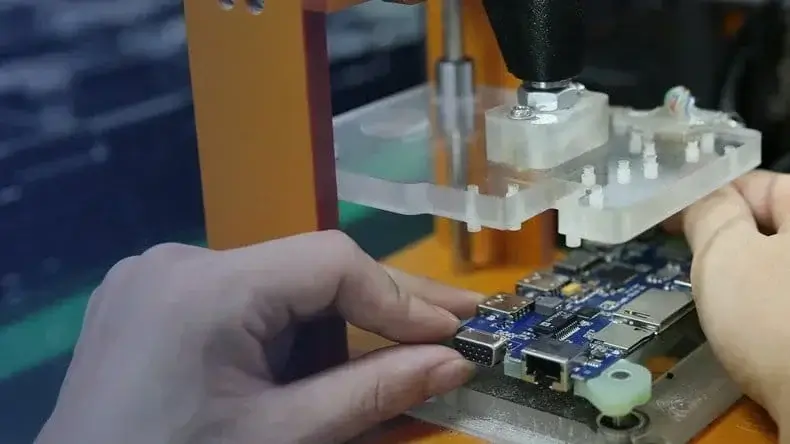

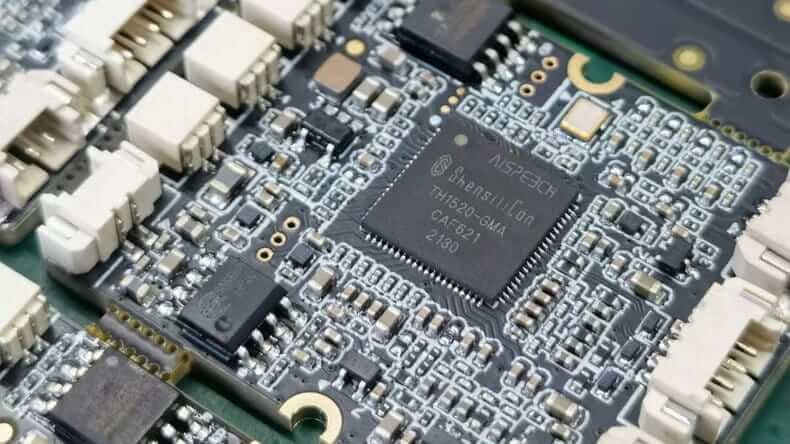

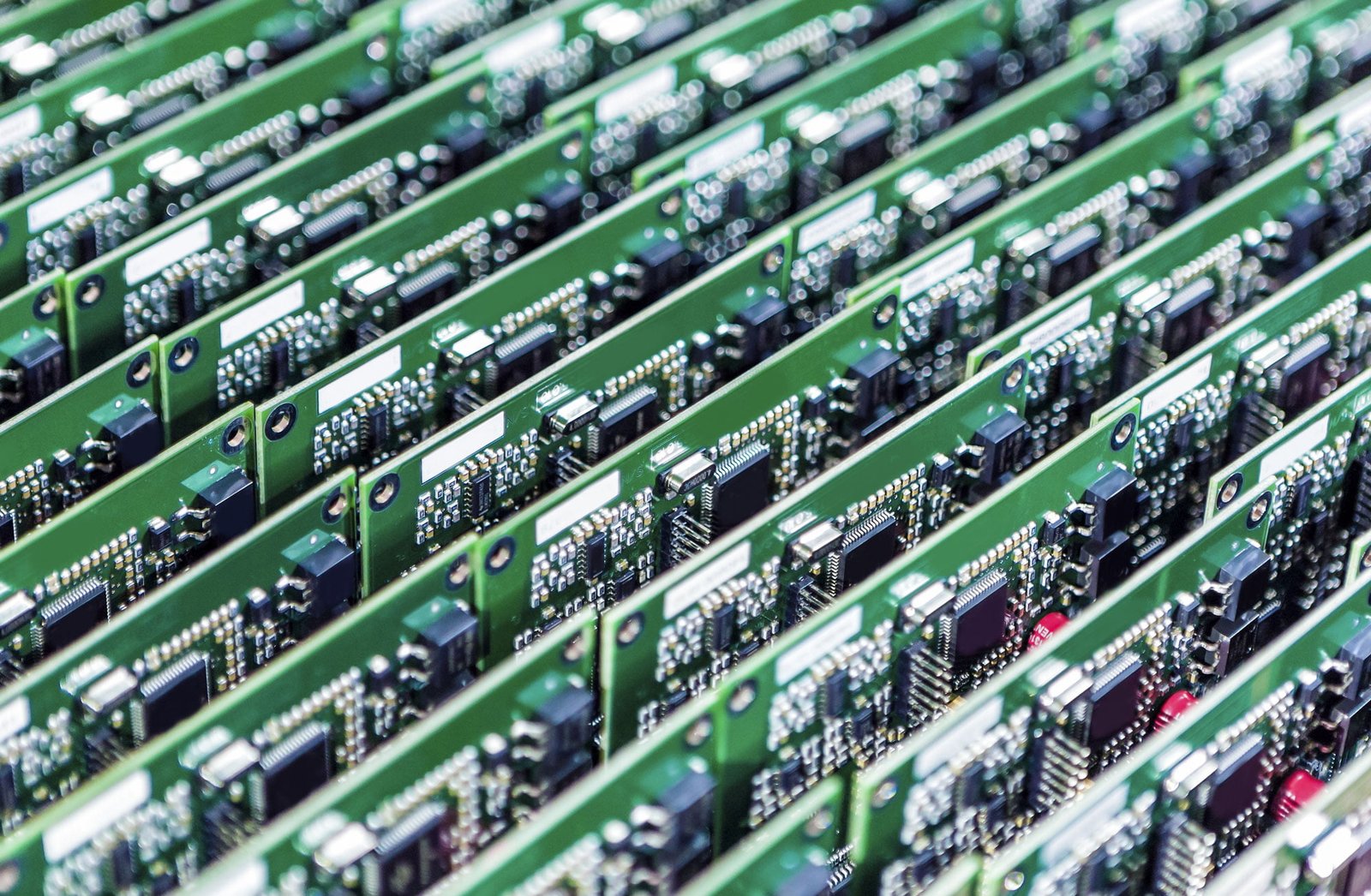

Our expertly engineered manufacturing services lay the foundation for smarter devices and seamless integration. Trust Kenoxis Technologies to deliver efficiency, reliability, and scalability every step of the way. Our team comprises experienced engineers, product designers, quality inspectors, and R&D specialists, all working in unison to bring innovative ideas to life.

Get in Touch

Contact Us

Email address

support@kenoxistechnologies.com

Phone Number

+1 855-673-5515

Office Address

1639 Western Park CT,

Dallas, Texas 75211, USA